Overview

The RKI S2 series gas sensor/transmitters are highly reliable and very cost effective for the detection of common gas

hazards. The S2 series are available for LEL, H2 Specific (LEL, and ppm), Oxygen, H2S, CO, and for a variety of toxic

gases. The transmitters for LEL, H2 Specific, Oxygen, H2S, CO2, and Carbon Monoxide are explosion-proof with flame

arrestors, and approved for use in hazardous areas (Class l, Div 1 Groups B, C, D). An optional non-explosion proof

version is available for oxygen, H2S, CO, and CO2 in Class 1 Div 2. LEL sensors are available using catalytic bead and

infrared technologies.

The toxic sensors are electrochemical type plug-in sensors, which provide high specificity, fast response, and long life.

The plug-in design allows quick replacement in the field with no tools required. Toxic sensors are designed for use in

Class I, Div. 2 hazardous locations. Sensors available for NH3, AsH3, Cl2, ClO2, HCN, PH3, and SO2.

The S2 transmitters can be used either indoors or outdoors. The flame arrestors for the explosion-proof versions

utilize a patented coating which make them water repellent. Splash guards are also available for use in very wet

environments. An optional stainless steel junction box is available for corrosive environments.

All of the S2 transmitters are designed to interface with RKI controllers, or with PLC/DCS systems.

Related Services

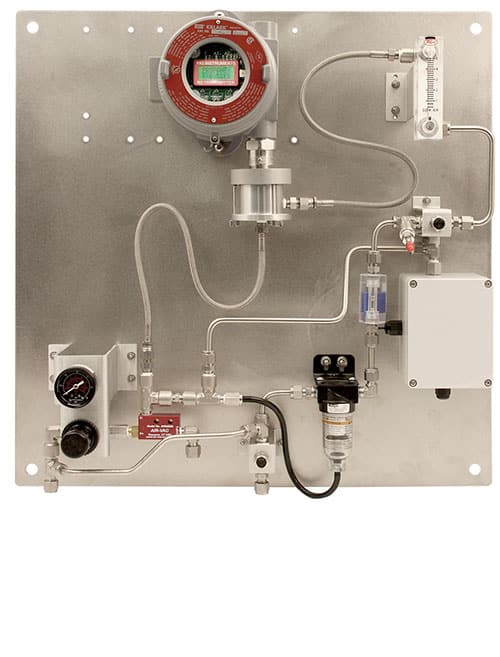

Fixed Systems Turnkey Solutions

- Design, Consultations, and Engineering

- Installation

- Start-up

- Training

- System Maintenance